Family Sites

Technical Services

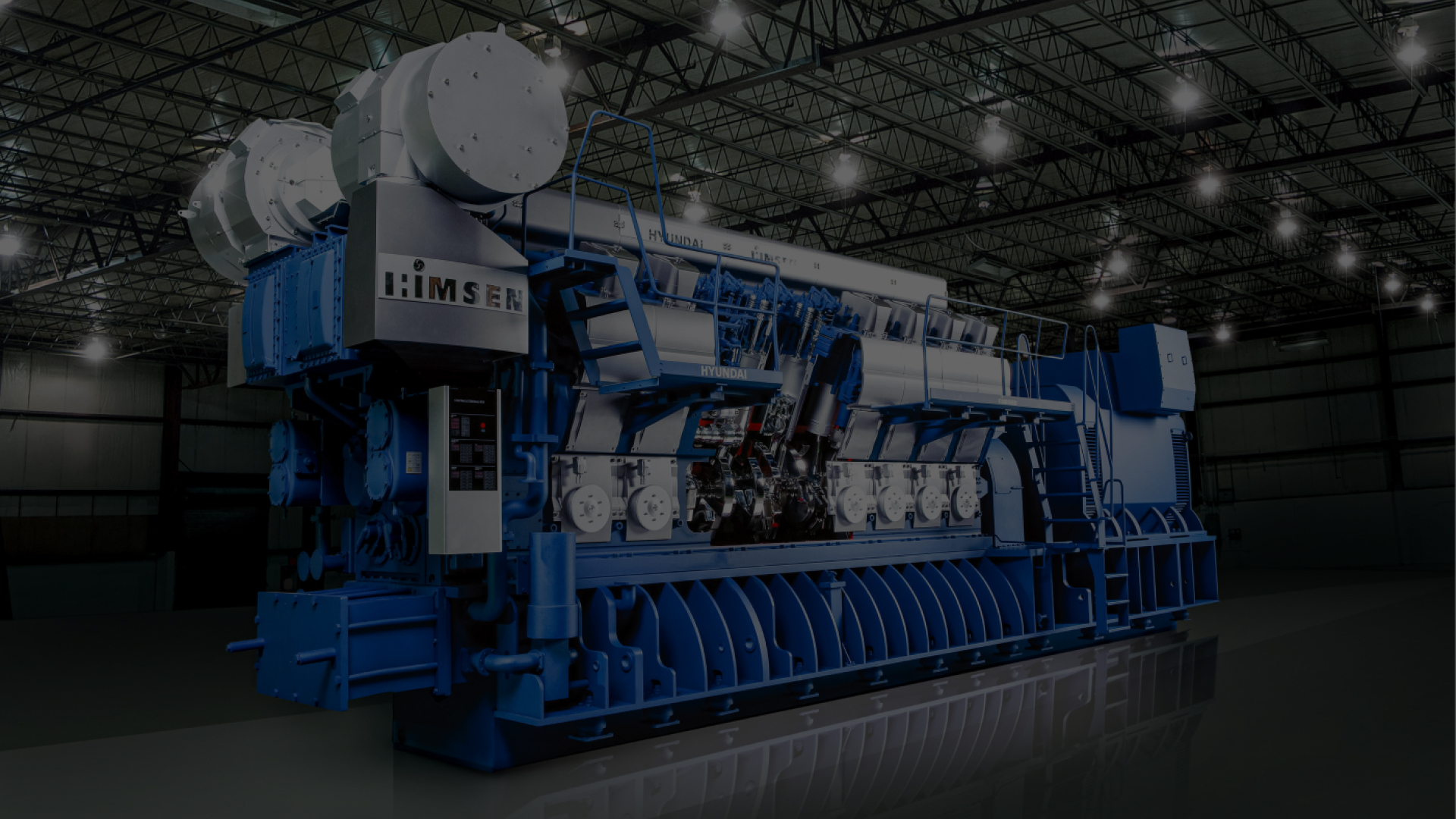

HiMSEN Engines

We lead the future of the vessel maintenance industry with world-class HiMSEN engines and engineering capabilities.

-

As an engine maker, HD Hyundai Marine Solution Tech prioritizes customer satisfaction,

providing after-sales service and customized design, analysis, and retrofit solutions.

-

Based on abundant field experience and extensive technical and drawing data,

we provide rapid and high-level technical solutions for diverse and complex problems.

-

We dispatch engineers to vessels worldwide to offer specialized services such as Overhaul,

Retrofit, and Troubleshooting, and we will further strengthen competitiveness

through continuous differentiation strategies.

HYUNDAI MARINE SOLUTION TECH

Through regular maintenance

by HiMSEN engine specialist engineers,

we ensure smooth workflow and

rapid response to unexpected situations.

Key Features

We perform work safely and quickly through accurate measurements and meticulous work on critical components.

-

LTSA

Long-Term Service Agreement

-

Major O/H

8,000 / 16,000 / 24,000 / 32,000 Hour Interval Overhaul Services

-

Recondition

We provide reconditioning of all significant parts, including cylinder heads, liners, pistons, and pumps, at verified workshops.

We review and propose engine performance

optimization retrofit plans from multiple angles to

meet customer requirements and standards.

Key Features

We propose solutions that realize the performance customers want through customized engine retrofits.

-

Re-Engine

Installation of a New Engine

-

ECS

Retrofit to AVAT Engine Control System (ECS), Including Local Control Panel (LOP) and WAGO PLC.

-

EPLO

Engine Power Limitation Optimization

We diagnose problems during vessel

operation and provide solutions via

remote support or engineer dispatch.

Key Features

We offer specialized technical support through root-cause analysis and problem diagnosis, and on-site engineering support when necessary.

-

Exhaust Temp High

Perform tuning and inspect the overall exhaust and combustion system

-

RPM Hunting

Inspect the governor system and Engine Control System (ECS)

-

Vibration

Measure vibration levels and install balancing weights or reinforce the base frame as necessary

Based on extensive experience, we investigate accident

causes and provide comprehensive recovery work,

from preparing recovery material lists to

actual performance and commissioning.

Key Features

We provide specialized technical support through root cause analysis and problem diagnosis, and on-site engineering support when necessary.

-

Root Cause Analysis

Analysis of failure or incident root causes

-

Optimization

Optimization of engine parameters for performance and efficiency

-

Heavy Part Replacement

Replacement of major components such as crankshaft or engine block

We identify phenomena in advance based on vessel

engine operation habits and methods, and recommend

incorporating countermeasures during future

overhauls to support safe and efficient operation.

Key Features

We perform work within a short berthing time, diagnose overall engine problems, and advise on additional necessary matters.

-

Inspection

We provide customized diagnostic services for each engine, such as reviewing Overhaul cycles through departure inspection and re-determining the Life Time of each Part.

-

Spare Parts List Preparation

Based on the Inspection report, we provide a list of necessary materials in addition to spare parts required for regular Maintenance to ensure the engine achieves optimal performance.

-

Performance Data Monitoring and Advisory

We collect Performance Data for each engine and provide performance improvement advice.

Now Loading.

Please wait a moment.

HD한국조선해양의 모바일 웹은 세로화면에 최적화되어 있습니다.